It consists of several different material parting operations such a piercing perforating shearing notching cutoff and blanking.

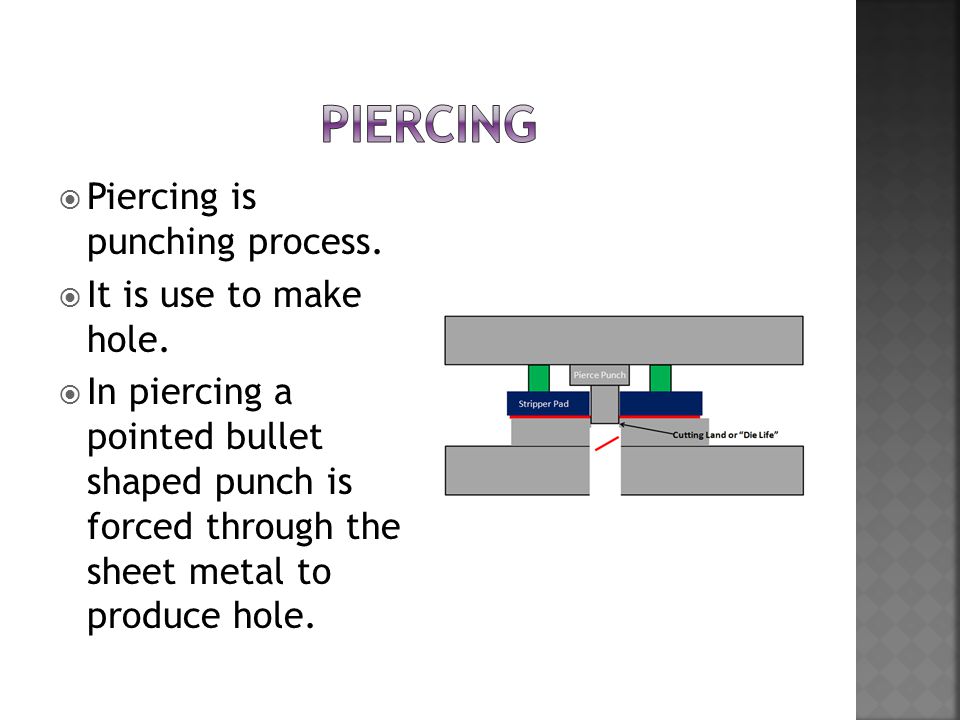

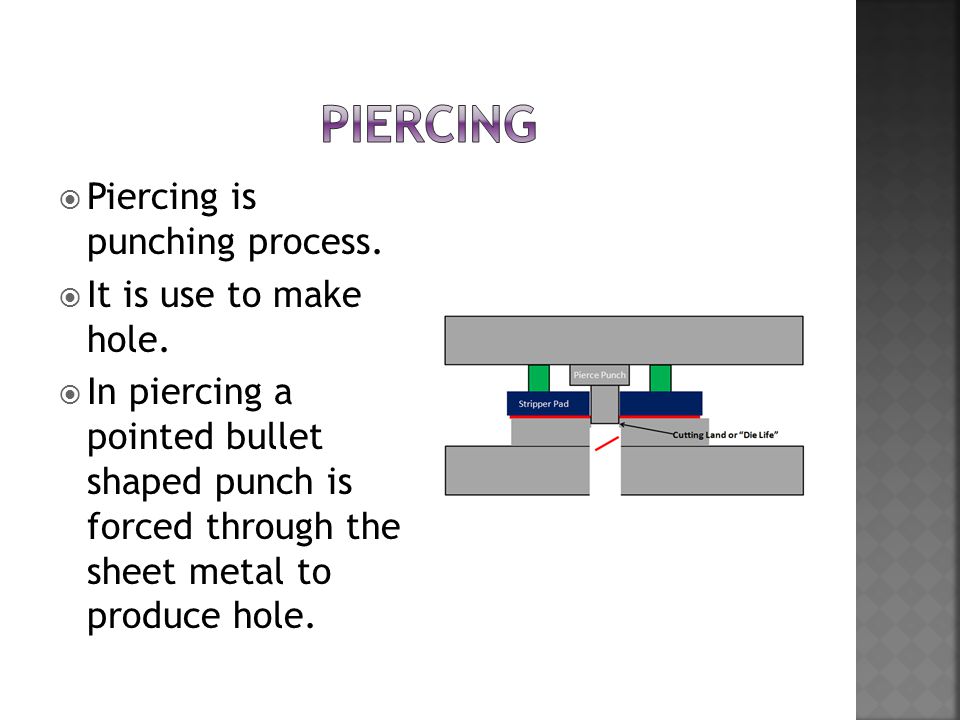

Piercing process in sheet metal.

Piercing does not break through the metal s surface like a drilling operation.

It can be used to create a cavity or hole in the work piece.

Blanking produces the outside features of the component while piercing produces internal holes or shapes.

As a result of applied force from the piercing tool sheet metal starts tearing and produces extruded hole slot.

The metal from the freshly formed hole is regarded scrap as the raw metal is penetrated.

Piercing is a shearing method in which raw metal with a machining instrument is penetrated leading in a circular or other shaped hole being created.

Blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock.

Sheet metal powder processes metal piercing piercing is a metal forging technique that is often performed as an auxiliary process in conjunction with other forging processes in the manufacture of a part.

In other words piercing operation produces an extruded hole in sheet metal.

The slugs produced by piercing internal features are also considered scrap.

The piercing machine pushes through the sheet metal a device known as a blanking punch.

In blanking the piece is cut off from the sheet and it becomes a finished part.

Both blanking and piercing are shearing operations.

In case of piercing or punching the material which is cut out from the sheet metal is scrap and the reining material is the actual part.

Piercing operation produces an extruded hole or slot.

It is one of the most extensively used processes throughout die and sheet metal work.

The process and machinery are usually the same as that used in blanking except that the piece being punched out is scrap in the piercing process.

Piercing is a shearing process in which raw metal is pierced with a machining tool resulting in the creation of a circular or other shaped hole.

The web is created after multiple components have been produced and is considered scrap material.

The piercing machine forces a tool known as a blanking punch through the sheet metal.

Piercing is the operation of punching holes in the sheet metal.

Difference between blanking and piercing.

As the raw metal is pierced the metal from the newly created hole is considered scrap.