Punching is a cutting process.

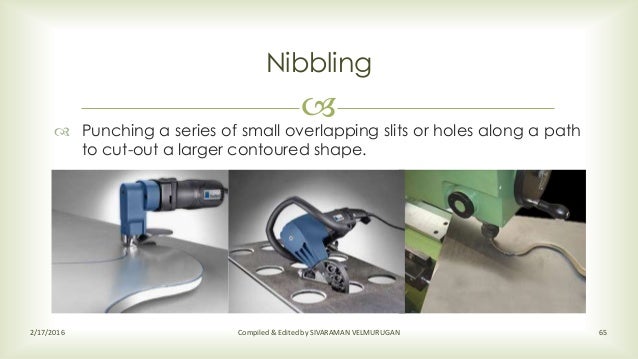

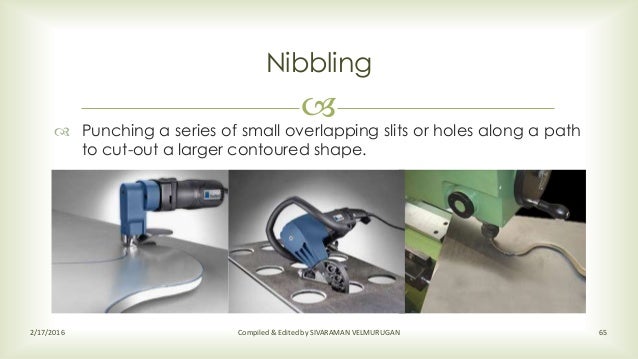

Nibbling process in sheet metal.

The way of cutting sheets with nibbler is to cut punches out of a tiny metal sheet and repeat the process until you get your desired dimension.

Nibbling is when a large number of holes are punched in sheet metal.

This allows for complex shapes to be formed in sheet metal up to 6 mm 0 25 in thick using simple tools.

So let s take a quick look at the usage process of a nibbler step 1.

Punching is a fast effi cient productive and automated process and offers an enormous range of options.

Punching nibbling is suitable for thin sheets up to 3 mm and makes it possible to deform the material eyes small folds stamped parts threading.

One type operates much like a punch and die with a blade that moves in a linear fashion against a fixed die removing small bits of metal and leaving a kerf approximately 6 mm wide.

This process combines forward movement of the sheet that is being cut with vertical movement of the cutting tool.

Remember you won t expect a perfect finish with a so called good nibbler.

They have own the expert s trust with actual performance and dedication.

If a larger piece of sheet metal is to be removed it is also possible to nibble along its contours to do the process more efficiently.

A tool like a nibbler is fast and easy to maneuver around to cut circles corners and angles in sheet metal work with out jamming like electric shears or tin snips would.

Rapid make paradise brand sheet metal nibbling machine available in three models pn 3 pn 5 pn 8.

Another type operates similar to tin snips but shears the sheet along two parallel tracks 3 6 mm apart rolling up the waste in a tight spiral as it cuts.

The sheet moves under the press containing the tool.

Punches are available in various shape and sizes.

Around 300 900 times per minute.

Oblong and rectangular punches are common because they minimize waste and allow for greater distances between strokes as compared to a.

Punching nibbling is a process that removes the material by making holes classic punching or by cutting inner or outer profiles by means of multiple punching strokes nibbling.

Apart from hand nibbler there are electric nibbler drill powered nibbler and pneumatic nibblers and so on.

The best tool to cut sheet metal is an electric nibbler tool it cuts corrugated iron sheet metal and even metal car panels easily.

First of all get a strong nibbler to cut the metal sheet.

Of virtually any shape and size.

Forming opens up new dimensions.

The nibbling process cuts a contour by producing a series of overlapping slits or notches.

A sheet is cut in two with a single stroke.

As the holes overlap it is possible to remove material without the need for special tools.

The result is a contour.

A nibbler or nibblers is a tool for cutting sheet metal with minimal distortion.