2 to 3 passes are generally required and intermediate annealing may be necessary in some cases to get the correct angle of flange.

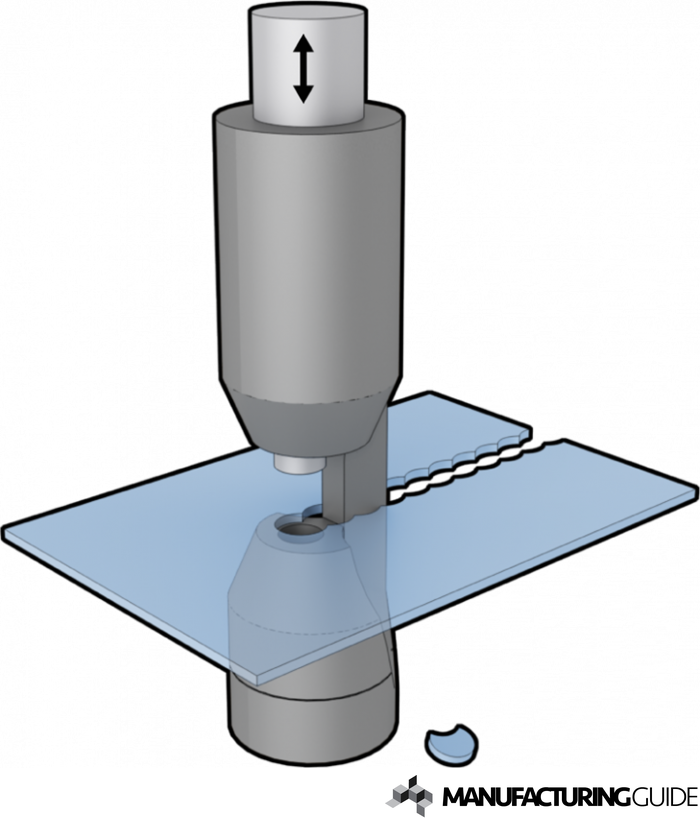

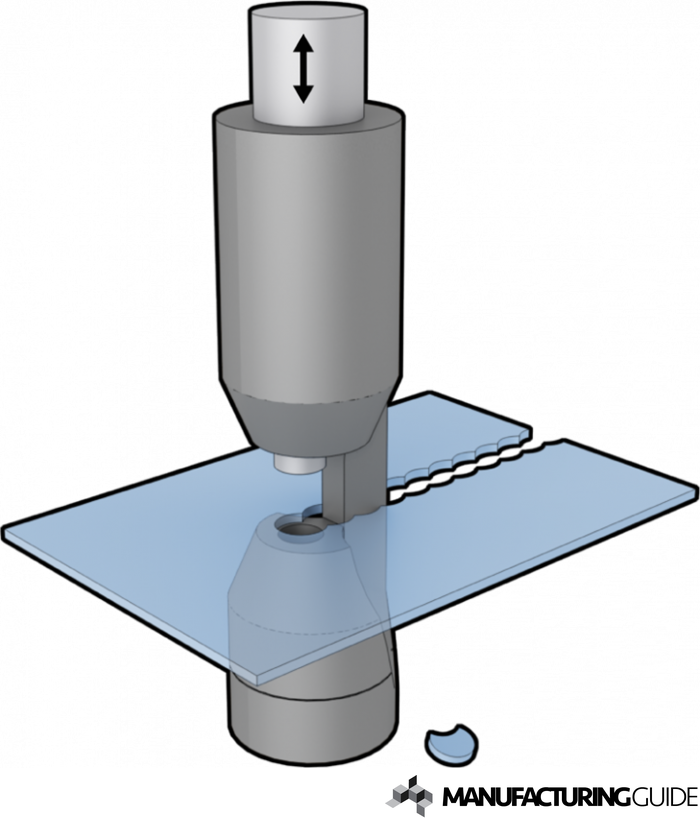

Nibbling operation in sheet metal.

Get it as soon as sat sep 19.

Flanging is a forming operation very commonly used on sheet metal parts.

If a 60 mm punching tool is not available.

Combinations of a series of punches of small diameter such as 2 mm can be used to cut a 60 mm hole.

One type operates much like a punch and die with a blade that moves in a linear fashion against a fixed die removing small bits of metal and leaving a kerf approximately 6 mm wide.

Tools are available for straight cutting figure cutting contour cutting and circle cutting operations.

Bending is the operation of deforming a sheet around a straight axis.

This allows for complex shapes to be formed in sheet metal up to 6 mm 0 25 in thick using simple tools.

Blank is the required product of the operation.

The neutral plane lies on this straight axis.

Nibbling operation to cut sheet metal part.

0 o to 90 o flanging is possible by changing the lower tool.

The nibbling process cuts a contour by producing a series of overlapping slits or notches.

A nibbler or nibblers is a tool for cutting sheet metal with minimal distortion.

Another type operates similar to tin snips but shears the sheet along two parallel tracks 3 6 mm apart rolling up the waste in.

It is the operation of cutting away excess metal in a flange or flash from a sheet metal part using suitable punch and die of press tool in press machine.

In sheet metal operations the metal is sheared hence also called as shearing operations.

For example if the requirement is to cut a 60 mm hole in the sheet metal part.

Rapid make paradise brand sheet metal nibbling machine available in three models pn 3 pn 5 pn 8.

The paradise pn series sheet metal nibbling machine is a rugged sturdy reliable multipurpose machine capable of many sheet cutting forming operations.

Free shipping by amazon.